M-Pipe & Fitting Solution Inc is a reputable company that manufactures and supplies high-quality duplex steel UNS S31803 sheets & plates. Duplex Steel UNS S31803 is a popular duplex stainless steel grade with excellent corrosion resistance, high strength, and good weldability. It is composed of a balanced microstructure consisting of ferrite and austenite phases, which provides it with unique properties. This article provides an in-depth overview of Duplex Steel UNS S31803 Sheets & Plates, highlighting their key features, applications, and benefits.

Composition and Properties: Duplex Steel UNS S31803 Sheets & Plates comprise various elements, including chromium, nickel, molybdenum, and nitrogen. The typical chemical composition of Duplex Steel UNS S31803 is as follows:

Chromium (Cr): 21-23%

Nickel (Ni): 4.5-6.5%

Molybdenum (Mo): 2.5-3.5%

Nitrogen (N): 0.08-0.20%

Iron (Fe): Balance

Combining these elements imparts remarkable properties to Duplex Steel UNS S31803, making it suitable for various applications.

Key Features and Benefits:

Corrosion Resistance: Duplex Steel UNS S31803 exhibits excellent resistance to various corrosive environments, including chloride-containing and acidic solutions. It makes it highly suitable for chemical, petrochemical, and marine applications.

High Strength: The duplex microstructure of UNS S31803 provides significantly higher strength than austenitic stainless steels. It offers good tensile and yield strength, enabling it to withstand heavy loads and pressures.

Good Weldability: Duplex Steel UNS S31803 is known for its good weldability, allowing for easy fabrication and joining. It can be welded using conventional welding techniques, making it suitable for various construction and fabrication projects.

Excellent Toughness: The combination of ferrite and austenite phases in UNS S31803 imparts exceptional toughness, enabling it to withstand impacts and shocks without undergoing brittle fracture. This property is particularly advantageous in applications exposed to dynamic loads.

Products and Applications:

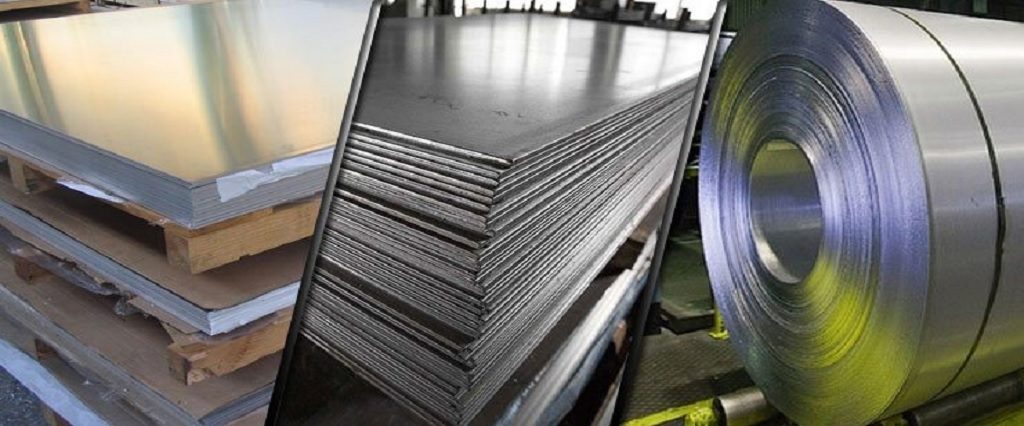

Duplex Steel S31803 Sheets: These are thin, flat components of Duplex Steel UNS S31803, widely used in industries such as chemical processing, oil and gas, desalination plants, and pulp and paper. They are suitable for applications requiring corrosion resistance and high strength.

Duplex Steel S31803 Plates: Plates made from UNS S31803 are thicker and more prominent in size, designed to withstand higher loads and pressures. They find applications in heat exchangers, pressure vessels, structural components, and offshore platforms.

Duplex Steel S31803 Shim Sheets: Shim sheets are thin, and tapered for precise alignment and leveling. They are commonly employed in machinery, tooling, and construction industries. The corrosion resistance and strength of UNS S31803 make it an ideal material for shim sheets.

Duplex Steel S31803 Metal Plates: Metal plates made from UNS S31803 are heavy-duty components used in critical applications, such as chemical reactors, storage tanks, and power generation equipment. They offer excellent strength, corrosion resistance, and durability.

Duplex Steel UNS S31803 Sheets & Plates are versatile materials that combine the benefits of both ferritic and austenitic stainless steels. Their unique microstructure, outstanding corrosion resistance, high strength, and good weldability make them suitable for various demanding applications. Whether in the chemical, petrochemical, oil and gas, desalination, pulp, and paper, or construction industries, Duplex Steel UNS S31803 Sheets & Plates offer reliable performance and longevity.

The corrosion resistance of Duplex Steel UNS S31803 makes it highly effective in chloride-rich environments, such as coastal areas or applications involving exposure to seawater. It exhibits resistance to pitting and crevice corrosion, common challenges in aggressive environments. This property ensures the longevity and reliability of the sheets and plates, reducing maintenance costs and downtime.

In the chemical and petrochemical industries, Duplex Steel UNS S31803 Sheets & Plates are used in various equipment, including reactors, heat exchangers, storage tanks, and pipelines. The high strength and toughness of the material enable it to withstand high pressures, temperature variations, and corrosive chemicals.

The oil and gas industry also extensively utilizes Duplex Steel UNS S31803 Sheets & Plates in offshore platforms, subsea pipelines, and equipment for oil and gas exploration and production. The material’s resistance to stress corrosion cracking and its ability to maintain mechanical properties in aggressive environments make it a preferred choice for such demanding applications.

In desalination plants, where seawater is converted into freshwater, Duplex Steel UNS S31803 Sheets & Plates are used in various components, such as evaporators, condensers, and heat exchangers. The material’s corrosion resistance and excellent thermal conductivity contribute to efficient and reliable desalination processes.

The pulp and paper industry relies on Duplex Steel UNS S31803 Sheets & Plates for equipment and machinery exposed to corrosive chemicals, high temperatures, and mechanical stress. These include pulp digesters, bleach towers, and paper machine components. The material’s combination of strength, corrosion resistance, and ease of fabrication make it suitable for the demanding conditions encountered in the industry.

In the construction sector, Duplex Steel UNS S31803 Sheets & Plates find applications in structural components, bridges, and architectural features. The material’s high strength-to-weight ratio allows for lighter and more cost-effective structures, while its corrosion resistance ensures durability and longevity in various environmental conditions.

In summary, Duplex Steel UNS S31803 Sheets & Plates offer many benefits, including corrosion resistance, high strength, good weldability, and toughness. These properties make them indispensable in chemical processing, oil and gas, desalination, pulp and paper, and construction. By choosing Duplex Steel UNS S31803 Sheets & Plates, engineers and designers can ensure their applications’ reliability, performance, and longevity in demanding environments. M-Pipe & Fitting Solution Inc provides certified sheet and plates that meet international standards such as API, ASTM, and ISO 9001:2015.

| Grades | Duplex Steel UNS S31803 |

| Standard | ASTM A240, A167 / ASME SA240, SA167 |

| Size | 1/4″ to 4″ |

| Thickness | 4.0mm – 100mm |

| Form | Foils, Shim Sheet, Rolls, Perforated Sheet, Plain Sheet, Chequered Plate, Coils, Rolls, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Finish | Hot rolled plate (HR), SATIN (Met with Plastic Coated), Cold rolled sheet (CR), 2B, 2D, BA NO(8) |

| Duplex Steel S31803 Sheets | Duplex S31803 Plates | Duplex Steel S31803 Coils |

| Duplex Steel S31803 Plates | Duplex S31803 Coils | Duplex UNS S31803 Flats |

| Duplex S31803 Shim Sheet | Duplex S31803 Chequered Plate | Duplex S31803 Strip |

| UNS S31803 Cold Rolled Sheet | Duplex S31803 Hot Rolled Plate | Duplex Steel S31803 Circle |

| Duplex S31803 Plate | Duplex S31803 Sheet | Duplex 3S31803 Forging Ring |

| Duplex Steel UNS S31803 Foils | Duplex Steel S31803 Flats | Duplex S31803 Perforated Sheet |

| Duplex UNS S31803 Rolls | Duplex S31803 Plain Sheet | Duplex S31803 Cold rolled sheet |

Cold rolled sheets and plates are manufactured by passing the hot rolled material through cold reduction mills. This process reduces the thickness of the material and imparts a smoother and more refined surface finish. Cold rolled sheets and plates exhibit improved dimensional accuracy and flatness. They are commonly used in applications requiring tight tolerances and a superior surface finish.

Construction Industry

Food Service Industry

Chemical Industry

Transportation Industry

Marine Industry

Textile Industry

Infrastructure Industry

- Duplex Steel 2205 Sheets & Plates

- Duplex Steel UNS S31803 Sheets & Plates

- Duplex Steel S32760 Sheets & Plates