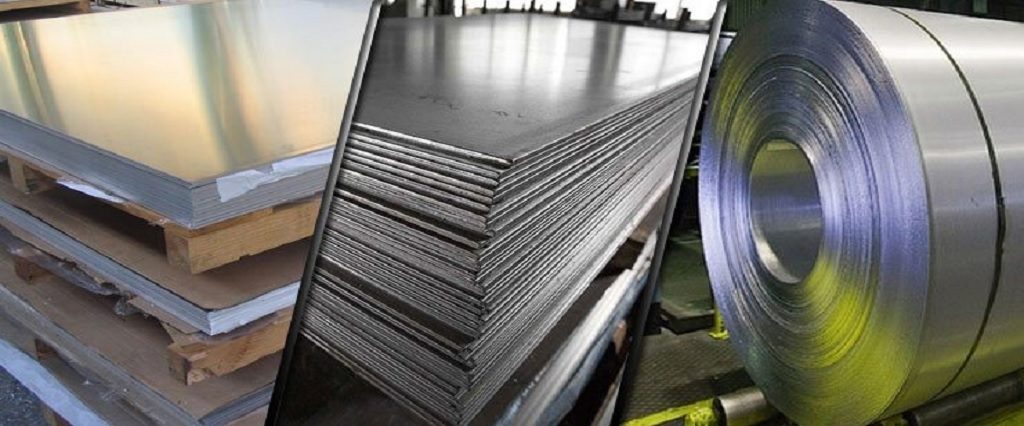

M-Pipe & Fitting Solution Inc is a reputable company that manufactures and supplies high-quality hastelloy sheets & plates. Hastelloy is a group of high-performance nickel-based alloys known for their exceptional corrosion resistance, high-temperature resistance, and excellent mechanical properties. Among the various types of Hastelloy alloys, Hastelloy C276 and Hastelloy C22 are widely used in industrial applications. This article will focus on Hastelloy C276 sheets and Hastelloy C22 sheets and coils, discussing their fundamental properties, applications, and benefits.

Hastelloy C276 Sheets:

Hastelloy C276 Sheets is a nickel-molybdenum-chromium alloy with excellent resistance to various corrosive environments. It offers outstanding resistance to pitting, crevice corrosion, stress corrosion cracking, and oxidizing atmospheres. Hastelloy C276 sheets are commonly available in various dimensions and thicknesses, making them suitable for diverse applications.

Properties of Hastelloy C276 Sheets:

Corrosion Resistance: Hastelloy C276 exhibits exceptional corrosion resistance in oxidizing and reducing environments. It is highly resistant to strong acids, such as sulfuric acid, hydrochloric acid, nitric acid, phosphoric acid, and alkaline solutions.

High-Temperature Resistance: Hastelloy C276 can withstand elevated temperatures and maintains its mechanical properties even at temperatures up to 1900°F (1040°C). This property makes it suitable for chemical processing, petrochemical, and power generation applications.

Mechanical Strength: Hastelloy C276 sheets offer excellent mechanical properties, including high tensile strength, good fatigue resistance, and low thermal expansion. These properties contribute to the alloy’s durability and reliability in demanding environments.

Fabricability: Hastelloy C276 can be easily formed, welded, and machined, allowing for the fabrication of complex shapes and components.

Applications of Hastelloy C276 Sheets:

Hastelloy C276 sheets find applications in various industries, including:

Chemical Processing: Hastelloy C276 is widely used in chemical processing plants for equipment such as reactors, heat exchangers, and piping systems, providing excellent resistance to corrosive chemicals.

Oil and Gas: The alloy is commonly employed in oil and gas production environments, including offshore platforms, where it resists the corrosive effects of seawater, sulfur compounds, and chlorides.

Pharmaceutical Industry: Hastelloy C276 sheets are utilized in pharmaceutical manufacturing equipment due to their resistance to corrosive media and ability to maintain product purity.

Pollution Control: The alloy is suitable for flue gas desulfurization systems, scrubbers, and other pollution control equipment due to its resistance to sulfuric acid and other corrosive gases.

Pulp and Paper Industry: Hastelloy C276 is used in paper and pulp processing equipment, offering excellent resistance to corrosive chemicals and high-temperature environments.

Hastelloy C22 Sheets & Coils:

Hastelloy C22 is another nickel-based alloy known for its exceptional resistance to various corrosive environments, including highly oxidizing and reducing conditions. It contains higher chromium content compared to Hastelloy C276, providing enhanced corrosion resistance in oxidizing media. Hastelloy C22 sheets and coils are available in various sizes and thicknesses to suit application requirements.

Properties of Hastelloy C22 Sheets:

Corrosion Resistance: Hastelloy C22 exhibits superior resistance to various corrosive environments, including sulfuric acid, hydrochloric acid, acetic acid, and wet chlorine gas. It is highly resistant to localized corrosion, such as pitting and crevice.

Versatility: Hastelloy C22 sheets offer excellent versatility due to their resistance to oxidizing and reducing environments. It makes them suitable for applications where exposure to various corrosive substances is expected.

High-Temperature Resistance: Hastelloy C22 demonstrates excellent high-temperature resistance, making it suitable for elevated-temperature applications. It can withstand temperatures up to 1250°C (2282°F) without significantly losing mechanical properties.

Weldability: Hastelloy C22 sheets can be readily welded using various methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. It allows for easy fabrication and assembly of complex structures and components.

Chemical Stability: Hastelloy C22 offers exceptional chemical stability, ensuring the integrity and longevity of equipment and components even in highly corrosive environments.

Applications of Hastelloy C22 Sheets:

Hastelloy C22 sheets find extensive use in various industries and applications, including:

Chemical Processing: Hastelloy C22 is widely employed in chemical processing industries, including reactors, vessels, and piping systems handling aggressive chemicals such as sulfuric acid, acetic acid, and chlorides.

Pharmaceutical Industry: The excellent corrosion resistance of Hastelloy C22 makes it suitable for pharmaceutical applications, including manufacturing equipment, reactors, and storage vessels that come into contact with corrosive chemicals.

Pollution Control: Hastelloy C22 sheets are utilized in pollution control equipment, such as scrubbers, exhaust systems, and flue gas desulfurization systems, offering resistance to sulfur compounds and corrosive gases.

Marine and Offshore: Due to its exceptional resistance to seawater and brine solutions, Hastelloy C22 is extensively used in marine and offshore applications, including seawater cooling systems, desalination plants, and offshore platforms.

Pulp and Paper Industry: Hastelloy C22 finds applications in pulp and paper processing equipment, including digesters, bleach plants, and evaporators, where it provides resistance to corrosive chemicals and high temperatures.

Aerospace Industry: Hastelloy C22 is utilized in aerospace applications, such as gas turbine engines, due to its high-temperature strength, corrosion resistance, and resistance to thermal fatigue.

UNS N06022 and UNS N10665:

UNS N06022 and UNS N10665 are the respective ASTM designations for Hastelloy C22 and Hastelloy C276. These designations specify the chemical composition, mechanical properties, and other characteristics of the alloys, ensuring consistency and compatibility in various industries and applications.

In summary, Hastelloy C276 sheets and Hastelloy C22 sheets and coils offer exceptional corrosion resistance, high-temperature resistance, and mechanical strength. They find extensive use in chemical processing, oil and gas, pharmaceutical, pollution control, pulp and paper, marine, aerospace, and other industries. Their versatility, fabricability, and ability to withstand corrosive environments make them reliable choices for critical applications where corrosion resistance is paramount. M-Pipe & Fitting Solution Inc provides certified Sheets & Plates that meet international standards such as API, ASTM, and ISO 9001:2015.

| Grades | Hastelloy C276, C22, B2 / UNS N10276, N06022, N10665 |

| Standard | ASTM B575, B333 / ASME SB575, SB333 |

| Size | 15NB to 150NB IN |

| Form | Foils, Shim Sheet, Rolls, Perforated Sheet, Plain Sheet, Chequered Plate, Coils, Rolls, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Finish | Hot rolled plate (HR), SATIN (Met with Plastic Coated), Cold rolled sheet (CR), 2B, 2D, BA NO(8) |

| Hastelloy C276 Sheets | Hastelloy C276 Plates | Alloy C276 Coils |

| Alloy N10276 Plates | Alloy C22 Coils | Hastelloy B2 Flats |

| Hastelloy B2 Shim Sheet | Alloy N10665 Chequered Plate | Hastelloy C276 Strips |

| Hastelloy C22 Cold Rolled Sheet | Alloy N06022 Hot Rolled Plate | Hastelloy C276 Circle |

| Hastelloy C276 Plates | Alloy B2 Sheets | Hastelloy C276 Forging Ring |

| Hastelloy B2 Foils | Alloy UNS N10276 Flats | Hastelloy C22 Perforated Sheet |

| Hastelloy C276 Rolls | Hastelloy B2 Plain Sheet | UNS N10665 Alloy Plate |

Hastelloy C276 alloy that are available in various dimensions and thicknesses. They are commonly used for applications requiring corrosion resistance and high temperature resistance.

Hastelloy C276 plates: Plates are thicker sections of Hastelloy C276 alloy, typically exceeding 6mm in thickness. They are used for applications that require strength and durability, such as pressure vessels and heat exchangers.

Construction Industry

Food Service Industry

Chemical Industry

Transportation Industry

Marine Industry

Textile Industry

Infrastructure Industry

- Hastelloy B2 Sheets

- Hastelloy C22 Sheets

- Hastelloy C276 Sheets

- Hastelloy B2 Plates

- Hastelloy C22 Plates

- Hastelloy C276 Plates

- Hastelloy B2 Coils

- Hastelloy C22 Coils

- Hastelloy C276 Coils