M-Pipe & Fitting Solution Inc is a reputable company that manufactures and supplies high-quality stainless steel 309l sheets & plates. Stainless Steel 904L Sheets & Plates are renowned for their exceptional corrosion resistance, high strength, and excellent formability. Widely used in various industries such as chemical processing, oil and gas, pharmaceuticals, and more, these sheets and plates offer superior performance in harsh environments.

- Superior Corrosion Resistance: Stainless Steel 904L Sheets & Plates are specifically designed to exhibit outstanding resistance to corrosion, making them suitable for challenging environments. These sheets and plates have high nickel, chromium, and molybdenum levels, contributing to their exceptional corrosion resistance properties. Whether exposed to harsh chemicals, acidic solutions, or saltwater, 904L Stainless Steel remains resistant to pitting, crevice, and general corrosion. It makes it an excellent material choice for applications in marine environments, chemical processing plants, and offshore oil rigs.

- High Strength and Durability: 904L Stainless Steel Sheets & Plates offer exceptional strength and durability, making them suitable for demanding applications. With a higher content of alloying elements like nickel and molybdenum, these sheets and plates exhibit excellent mechanical properties, including high tensile and yield strength. It enables them to withstand heavy loads and resist deformation, ensuring long-lasting performance in various industrial settings. The material’s high toughness and impact resistance further enhance its durability, making it suitable for critical applications such as pressure vessels, heat exchangers, and desalination plants.

- Excellent Formability and Weldability: One of the significant advantages of Stainless Steel 904L Sheets & Plates is their excellent formability and weldability. This grade of stainless steel can be easily fabricated into different shapes and sizes, allowing for customization according to specific project requirements. Whether you need sheets, plates, coils, or even intricate components, 904L Stainless Steel offers versatility in manufacturing processes. Moreover, these sheets and plates exhibit excellent weldability, ensuring strong and reliable joints. This characteristic is essential in applications where structural integrity is paramount, such as construction, architectural design, and automotive manufacturing.

- Wide Range of Applications: Stainless Steel 904L Sheets & Plates find extensive applications across various industries due to their exceptional properties. In the chemical processing industry, these sheets and plates produce reactors, tanks, and piping systems that handle corrosive chemicals. They are employed in offshore platforms, heat exchangers, and pipelines in the oil and gas sector. The pharmaceutical industry utilizes 904L Stainless Steel for equipment like storage tanks, process vessels, and pharmaceutical reactors. Other applications include desalination plants, pulp and paper manufacturing, food processing equipment, and architectural structures. The versatility, corrosion resistance, and durability of 904L Stainless Steel make it a preferred choice in these demanding industries.

- Unmatched Chemical Resistance: Stainless Steel 904L Sheets & Plates exhibit unmatched chemical resistance, making them highly suitable for corrosive media applications. The high levels of chromium, nickel, and molybdenum in 904L Stainless Steel provide exceptional resistance to various acids, including sulfuric acid, phosphoric acid, and acetic acid. This resistance extends to organic and inorganic chemicals, such as chlorides and sulfates, making it an excellent choice for environments with aggressive chemical exposure. Using 904L Stainless Steel ensures the longevity and integrity of equipment and structures, minimizing the risk of corrosion-related failures and reducing maintenance costs.

- Heat and Creep Resistance: Stainless Steel 904L Sheets & Plates excellent heat and creep resistance is another noteworthy characteristic. The alloy’s high chromium and nickel content and low carbon contribute to its ability to withstand high temperatures and resist deformation under load. This property is crucial in applications with elevated temperatures, such as heat exchangers, furnace components, and thermal processing equipment. The superior creep resistance of 904L Stainless Steel allows it to maintain its structural stability even under prolonged exposure to high temperatures, ensuring the long-term reliability of the equipment.

- Hygienic and FDA-Approved Material: 904L Stainless Steel Sheets & Plates are highly suitable for pharmaceutical, food processing, and dairy applications due to their sanitary properties. This material is non-reactive, non-toxic, and resistant to bacterial growth, ensuring the products’ and processes’ integrity and safety. Stainless Steel 904L complies with FDA (Food and Drug Administration) regulations, making it an ideal choice for equipment used in producing and storing pharmaceuticals, beverages, dairy products, and food items. The easy cleanability of 904L Stainless Steel further contributes to maintaining strict hygiene standards and preventing contamination, making it a preferred material in industries with stringent sanitary requirements.

- Longevity and Cost Efficiency: Investing in Stainless Steel 904L Sheets & Plates ensures long-term durability and cost efficiency. The exceptional corrosion resistance and mechanical properties of 904L Stainless Steel result in equipment and structures with extended service life, reducing the need for frequent replacements and repairs. This longevity translates into significant cost savings over time. Additionally, the low maintenance requirements of 904L Stainless Steel further contribute to its cost efficiency. This material maintains its performance and appearance with minimal upkeep, such as routine cleaning and inspection, minimizing downtime and maintenance expenses. By choosing 904L Stainless Steel, you can achieve a balance between initial investment and long-term savings, ultimately enhancing the profitability of your operations.

Stainless Steel 904L Sheets & Plates offer unmatched corrosion resistance, high strength, excellent formability, and weldability, making them the optimal choice for demanding industrial applications. Their exceptional chemical resistance, heat resistance, and hygienic properties ensure reliable performance in corrosive environments, high-temperature conditions, and sanitary applications. Moreover, the longevity and cost efficiency of 904L Stainless Steel makes it a smart investment that delivers long-term durability and reduces maintenance costs. Regarding quality, performance, and value, Stainless Steel 904L Sheets & Plates are the ultimate solution for industries seeking reliable and efficient materials for their critical operations. Stainless Steel 904L Sheets & Plates offer outstanding corrosion resistance, high strength, excellent formability, and weldability. These qualities make them suitable for various industrial applications such as chemical processing, oil, gas, pharmaceuticals, etc. The superior performance of 904L Stainless Steel in harsh environments ensures the longevity and durability of equipment and structures. If you require a material that can withstand corrosive chemicals, extreme temperatures, and challenging conditions, Stainless Steel 904L Sheets & Plates are the perfect choice. Invest in high-quality 904L Stainless Steel to ensure optimal performance and peace of mind in your industrial applications. M-Pipe & Fitting Solution Inc provides certified sheet & plates that meet international standards such as API, ASTM, and ISO 9001:2015.

| Grades | Stainless Steel TP904L |

| Standard | ASTM A240 / ASME SA240 |

| Size | 1/4″ to 4″ |

| Thickness | 4.0mm – 100mm |

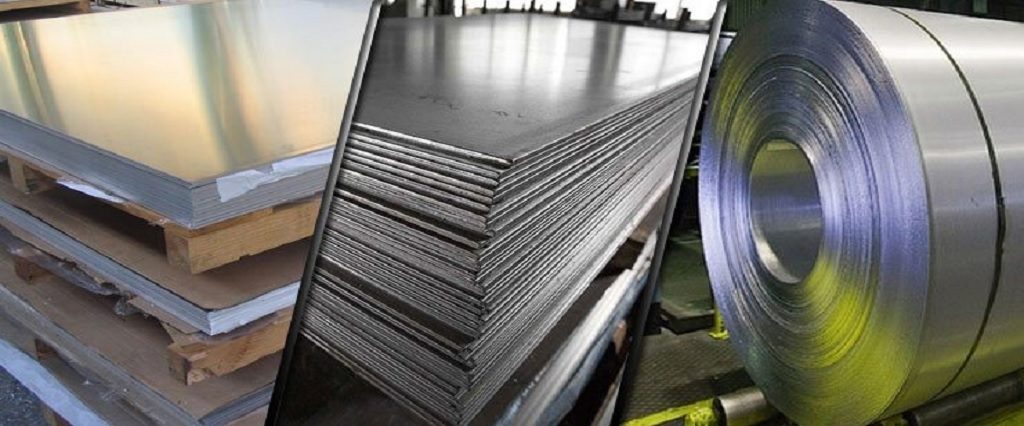

| Form | Foils, Shim Sheet, Rolls, Perforated Sheet, Plain Sheet, Chequered Plate, Coils, Rolls, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Finish | Hot rolled plate (HR), SATIN (Met with Plastic Coated), Cold rolled sheet (CR), 2B, 2D, BA NO(8) |

| Stainless Steel 904L Sheets | Steel UNS N08904 Plates | SS 904L Coils |

| Stainless Steel 904L Plates | Stainless Steel 904L Coils | Stainless Steel 904L Flats |

| Stainless 904L Shim Sheet | Steel 904L Chequered Plate | Steel 904L Strip |

| Steel 904L Cold Rolled Sheet | Steel 904L Hot Rolled Plate | Stainless Steel 904L Circle |

| Steel UNS N08904 Plates | Steel 904L Sheet | Steel 904L Forging Ring |

| Stainless Steel 904L Foils | Stainless Steel 904L Flats | Stainless Steel 904L Perforated Sheet |

| Stainless Steel 904L Rolls | Steel 904L Plain Sheet | Stainless Steel 904L Forging Ring |

All information in our datasheet is grounded on approximate testing and is stated formal of our knowledge & belief. It’s presented piecemeal from contractual scores and doesn’t constitute any guarantee of properties or of processing or operation possibilities in individual cases. Our guarantees and arrears are stated simply in our terms of trade.

Construction Industry

Food Service Industry

Chemical Industry

Transportation Industry

Marine Industry

Textile Industry

Infrastructure Industry

- Stainless Steel 304 Sheets, Plates & Coils

- Stainless Steel 304L Sheets, Plates & Coils

- Stainless Steel 310 Sheets, Plates & Coils

- Stainless Steel 310S Sheets, Plates & Coils

- Stainless Steel 316 Sheets, Plates & Coils

- Stainless Steel 316L Sheets, Plates & Coils

- Stainless Steel 317 Sheets, Plates & Coils

- Stainless Steel 317L Sheets, Plates & Coils

- Stainless Steel 321 Sheets, Plates & Coils

- Stainless Steel 347 Sheets, Plates & Coils

- Stainless Steel 904L Sheets, Plates & Coils